SiC Wafer Defect Inspection System, Global Market Size Forecast, Top 18 Players Rank (Business Opportunities - Advertising Service)

AUNetAds > Business Opportunities > Advertising Service

Item ID 2388214 in Category: Business Opportunities - Advertising Service

SiC Wafer Defect Inspection System, Global Market Size Forecast, Top 18 Players Rank | |

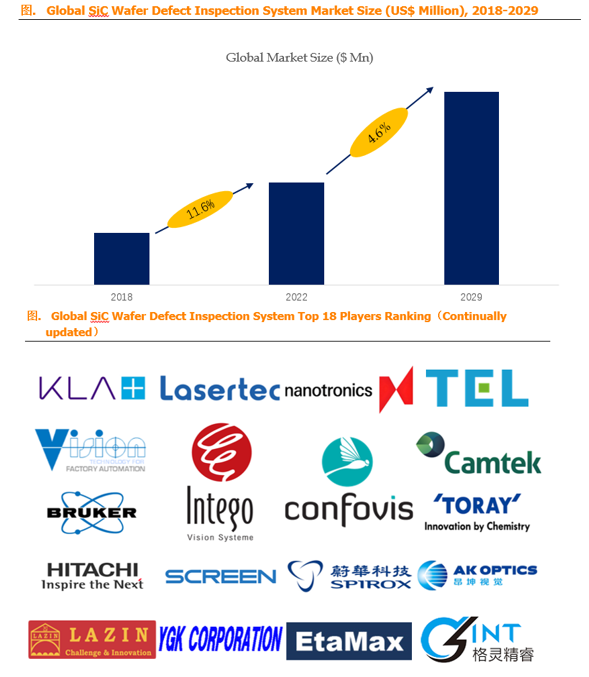

SiC Wafer Defect Inspection System Market Summary The SiC wafer defect detection system is a device used in the semiconductor industry to detect and analyze silicon carbide (SiC) wafer defects. SiC wafers are used to produce high-power and high-temperature electronic devices, such as power electronics and radio frequency (RF) devices. Defect inspection systems utilize advanced imaging techniques such as optical microscopy, scanning electron microscopy (SEM), and atomic force microscopy (AFM) to identify and characterize defects on the wafer surface. These defects may include particles, scratches, dents, cracks and other defects that may affect the performance and reliability of the electronic device. The system typically includes software that analyzes the captured images and provides quantitative data about the size, shape, and distribution of defects on the wafer. This information is crucial for quality control and process optimization during SiC device manufacturing. By using defect detection systems, manufacturers can identify and resolve potential issues early in the production process, thereby reducing yield losses and improving the overall quality of SiC wafers and their manufacturing equipment. Currently, typical products of SiC wafer defect detection systems include Kelei’s Surfscan® SP Ax, Lasertec’s SICA88, Nanotronics’s nSpec PRISM™, etc. On November 28, 2023, Spirox, a professional brand of semiconductor testing solutions, joined hands with its digital optics brand Southport to jointly launch the industry's first JadeSiC-NK non-destructive SiC defect detection system, which uses advanced nonlinear optical technology to inspect SiC substrates. Scan the entire film to find fatal crystal defects inside the substrate to replace the current high-cost and destructive KOH (potassium hydroxide) etching detection method. According to the new market research report "Global SiC Wafer Defect Inspection System Market Report 2023-2029", published by QYResearch, the global SiC Wafer Defect Inspection System market size is expected to reach USD 1.05 billion by 2029, at a CAGR of 4.6% during the forecast period. This report profiles key players of SiC Wafer Defect Inspection System such as KLA Corporation, Lasertec, Nanotronics, Tokyo Electron, Hitachi, Intego GmbH, Visiontec, Toray Group, Confovis, Angkun Vision, Camtek, Bruker, SCREEN Semiconductor Solutions, EtaMax, Shenzhen Glint Vision, LAZIN Co, YGK Corporation, Spirox. In 2022, the global top three SiC Wafer Defect Inspection System players account for 50% of market share in terms of revenue. Above figure shows the key players ranked by revenue in SiC Wafer Defect Inspection System. For more information, please contact the following e-mail address: Email: global@qyresearch.com Website: https://www.qyresearch.com  | |

| Target State: All States Target City : All Cities Last Update : 01 April 2024 1:20 PM Number of Views: 100 | Item Owner : Diana Contact Email: (None) Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

AUNetAds > Business Opportunities > Advertising Service

© 2025 AUNetAds.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-04-01 (0.757 sec)