Global Top 14 Companies Accounted for 82% of total Printing Blanket market (QYResearch, 2021) (Business Opportunities - Home Business)

AUNetAds > Business Opportunities > Home Business

Item ID 2402359 in Category: Business Opportunities - Home Business

Global Top 14 Companies Accounted for 82% of total Printing Blanket market (QYResearch, 2021) | |

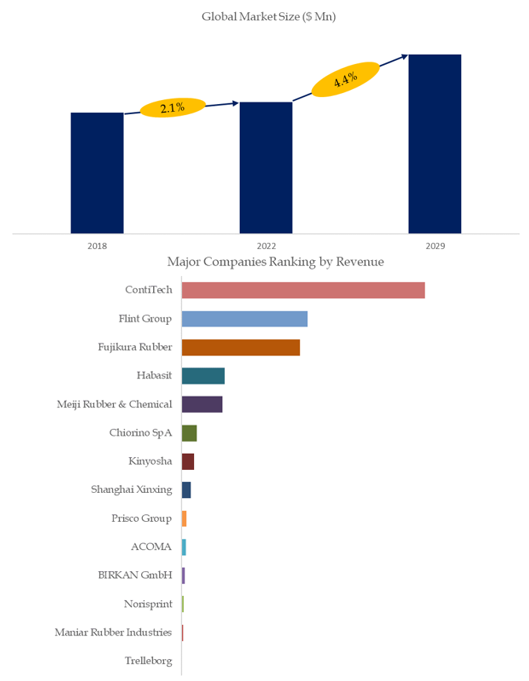

Printing Blanket, the cover of the transfer cylinder on an offset press, is an integral part of the liner. Printing Blanket A composite product consisting of a rubber coating and a substrate (substrates can range from paper to aluminum sheet to textiles to any other substrate such as plastic or metal.) for indirect lithography, transferring ink from the printing plate onto the substrate. During the manufacturing process, the fabric and rubber are combined using thermal and chemical energy in a precisely controlled process, and different compounds and structures give Printing Blankets different properties on the press. In the early days, Printing Blanket was made of pure rubber, and the image quality was much better than the lithographic printing plates used at the time, but it also had its drawbacks. The advent of synthetic rubber in the 1930s eliminated the problems inherent in the pure rubber previously used. Today, blankets are made by using different synthetic rubbers to increase their resistance. The main synthetic rubbers used today are Buna N, Neoprene as well as NVR (nitrile butadiene rubber), and EPDM (ethylene propylene diene rubber) to increase the durability of the blanket. To provide extra strength to the blanket, a backing with fabric or metal is provided. The global key manufacturers of Printing Blanket include ContiTech, Flint Group, Trelleborg, Fujikura Rubber, Habasit, Meiji Rubber & Chemical, Chiorino SpA, Kinyosha, Shanghai Xinxing, Prisco Group, etc. In 2022, the global top five players had a share approximately 82.0% in terms of revenue. For more information, please contact the following e-mail address: Email: global@qyresearch.com Website: https://www.qyresearch.com  | |

| Target State: All States Target City : All Cities Last Update : 28 April 2024 12:16 PM Number of Views: 83 | Item Owner : Mortimer Contact Email: (None) Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

AUNetAds > Business Opportunities > Home Business

© 2025 AUNetAds.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-02-05 (0.577 sec)